Address

Building 1, No. 22, Shexi Yongping Road,

Dongguan, Guangdong, China

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Building 1, No. 22, Shexi Yongping Road,

Dongguan, Guangdong, China

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

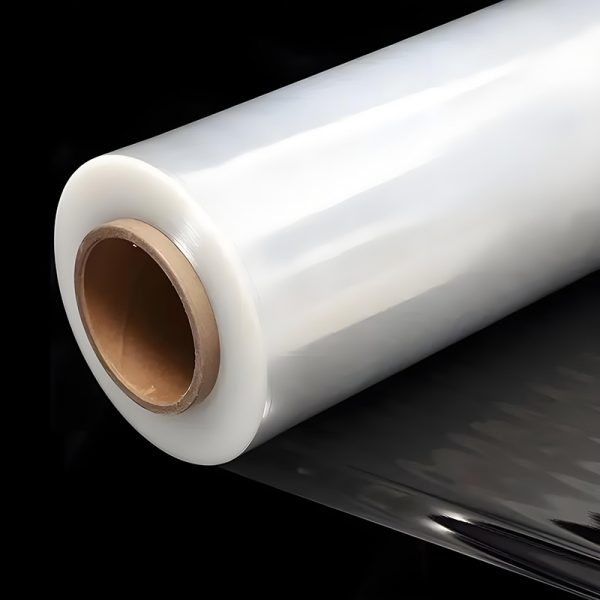

Mingskye presents the 55 – layer Nano Wrapping Film, a high – performance, energy – saving cast film leveraging nanolayer technology. As a new – type eco – friendly option, our film series (including antistatic, high – performance machine – use, and ultra – thin hand – use films) offers diverse choices.

With specifications covering machine – use and manual film types, these films boast properties like puncture resistance and tear resistance. Having passed tests such as RoHS and Reach, they deliver advantages like extreme thinness, excellent wrapping, and cost – effectiveness. Available in multiple models, we provide reliable wrapping film solutions with stable quality to meet diverse industrial packaging needs.

Our manager will prepare an excellent quote for you!

Product Parameters

Product Parameters

| Conventional Hand - Used Stretch Film Specification Models | |||

|---|---|---|---|

| Film Grade | Thickness (μm) | Ultimate Stretch (%) | Optimal Stretch (%) |

| High end Stiff Film (F) | 12 | 150 | 50% to 70% |

| 10 | 120 | 50% to 70% | |

| 8 | 100 | 50% to 70% | |

| Standard (A) | 23 | 300 | 250 |

| 20 | 270 | 230 | |

| 17 | 250 | 200 | |

| 15 | 250 | 200 | |

| Conventional Machine - Used Stretch Film Specification Models | |||

|---|---|---|---|

| Film Grade | Thickness (μm) | Ultimate Stretch (%) | Optimal Stretch (%) |

| Genius (D) | 15 | 400 | 280 - 300 |

| 12 | 350 | 250 - 280 | |

| Titan (K) | 15 | 350 | 250 - 280 |

| 12 | 320 | 240 - 280 | |

| Xeon (C) | 20 | 350 | 280 - 300 |

| 17 | 320 | 260 - 280 | |

| 15 | 300 | 230 - 280 | |

| Zeon (B) | 23 | 300 | 250 - 270 |

| 17 | 270 | 230 - 250 | |

| 12 | 250 | 200 - 230 | |

| Arteon (E) | 12 | 180 | 130 - 150 |

| 10 | 150 | 100 - 120 | |