Address

Building 1, No. 22, Shexi Yongping Road,

Dongguan, Guangdong, China

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

Building 1, No. 22, Shexi Yongping Road,

Dongguan, Guangdong, China

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

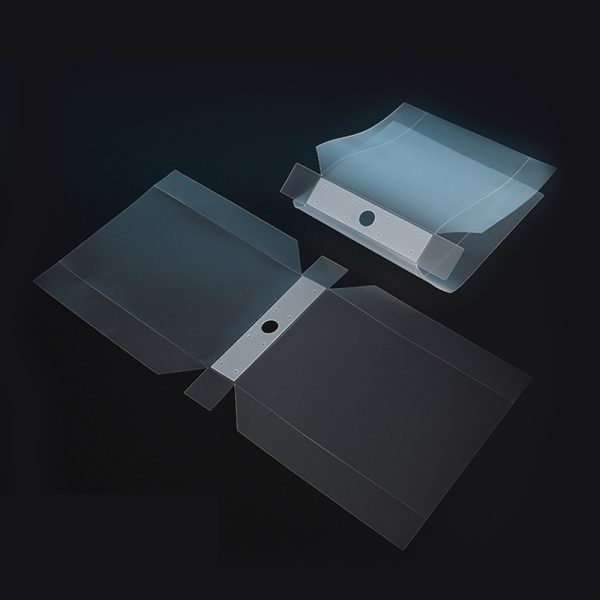

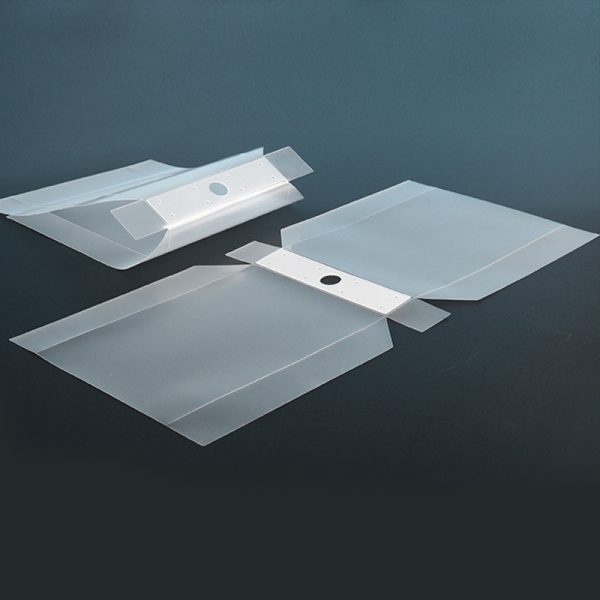

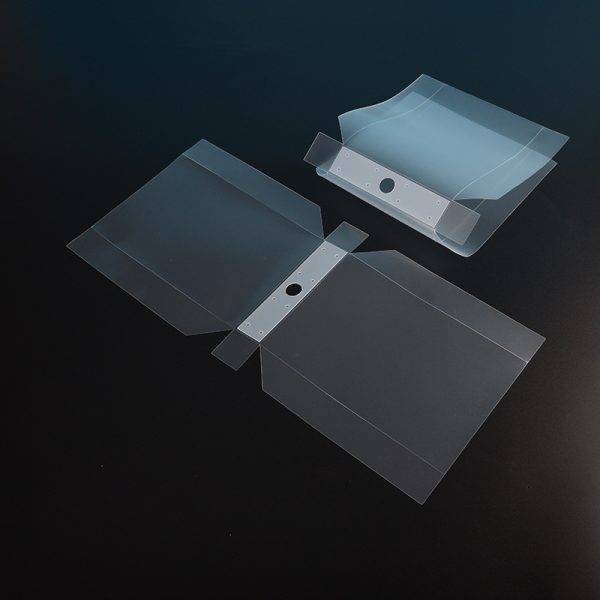

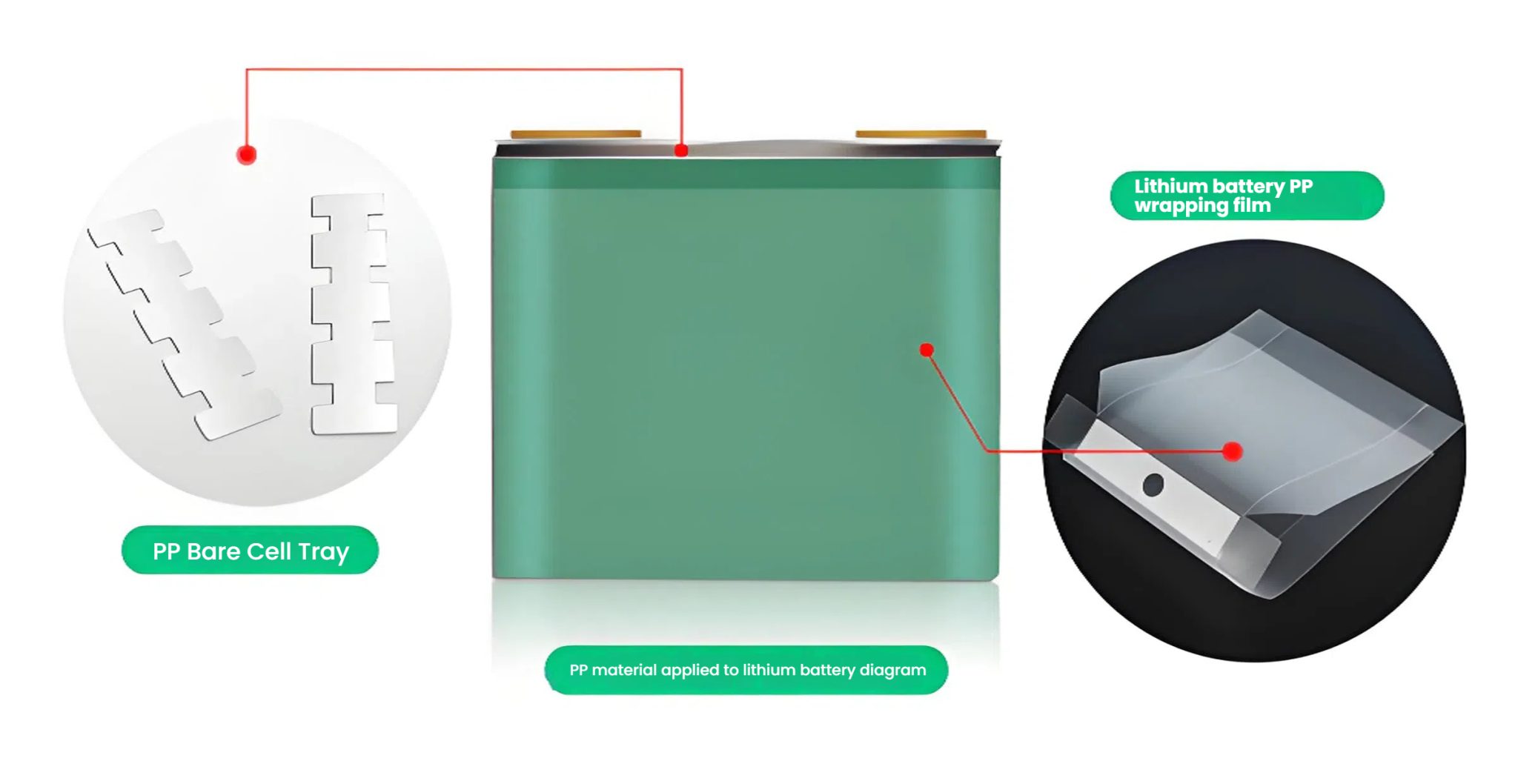

Mingskye focuses on PP materials for new energy vehicle lithium batteries. The developed PP films and sheets, verified by major market-end battery brands, feature excellent resistance to acid, alkali, and electrolytes, providing a solid foundation for lithium battery wrapping and cell separators.

Beyond new energy vehicles and the lithium battery industry, the materials are also suitable for multiple sectors such as coating and thermal transfer, supporting customization of specifications and appearance as needed. Having passed a series of strict tests, we offer product lines including PP wrapping films and positive/negative electrode reinforcement plates, delivering reliable material solutions for industry development with diverse parameters and stable quality.

Our manager will prepare an excellent quote for you!

| Lithium Battery - PP Wrapping Film Series | ||||||

|---|---|---|---|---|---|---|

| Item No. | Thickness | Texture | Color | Specific Gravity | Gram Weight | Ra Value |

| LDM - 005 | 0.05mm | Matte / Mirror | Natural Color | 0.91 | 43 | 0.2 - 1.2 |

| LDM - 008 | 0.08mm | Matte / Mirror | Natural Color | 0.91 | 73 | 0.2 - 1.2 |

| LDM - 010 | 0.10mm | Matte / Mirror | Natural Color | 0.91 | 91 | 0.2 - 1.2 |

| LDM - 015 | 0.15mm | Matte / Mirror | Natural Color | 0.91 | 137 | 0.2 - 1.2 |

| LDM - 020 | 0.20mm | Matte / Mirror | Natural Color | 0.91 | 182 | 0.2 - 1.2 |

| Lithium Battery Positive and Negative Electrode Reinforcement Plate (PP Thick Plate) | ||||||

|---|---|---|---|---|---|---|

| Item No. | Thickness | Texture | Color | Specific Gravity | Gram Weight | Ra Value |

| LDM - 030 | 0.3mm | Double Matte / Mirror | Natural Color | 0.91 | 273 | 0.2 - 1.2 |

| LDM - 050 | 0.5mm | Double Matte / Mirror | Natural Color | 0.91 | 455 | 0.2 - 1.2 |

| LDM - 080 | 0.8mm | Double Matte / Mirror | Natural Color | 0.91 | 728 | 0.2 - 1.2 |

| LDM - 100 | 1.0mm | Double Matte / Mirror | Natural Color | 0.91 | 910 | 0.2 - 1.2 |

| LDM - 150 | 1.5mm | Double Matte / Mirror | Natural Color | 0.91 | 1365 | 0.2 - 1.2 |

Mingskye PP lithium – ion battery films and sheets are mainly used for wrapping new energy vehicle lithium – ion batteries and as cell separators. The main functions of the materials include resistance to acid – base corrosion, resistance to electrolyte, wear resistance, resistance to high – low temperature impact, high compressive strength, insulation loading, and insulation resistance. The relevant PP materials have been verified and applied by major brand terminal lithium – ion batteries in the market.

The materials are mainly applied in new energy vehicles and the lithium – ion battery industry; other industrial applications of the materials include the coating industry, thermal transfer printing industry, electronics industry, home appliance industry, and mechanical processing industry. The materials can be customized in various specifications, sizes, appearances, and textures according to the performance requirements of each industry.

The materials have passed relevant tests such as RoHS, Reach, sulfur content test, UV aging test, puncture strength test, electrical strength test, high – low temperature impact aging test, high – temperature and high – humidity aging test, insulation resistance test, tensile shear strength test, tensile performance test, high – humidity resistance performance test, wear resistance test, compressive strength test, and salt spray test.